Cement & Lime

Rope Access Benefits

- Reduced downtime

- Reduced personnel, trained and licensed

- No scaffold

- Less heavy equipment

- Applicable to any type of structure

SUMMARY

TIME

Rope access rigging takes less than a day

COST

Smaller crew required; No potential costly failures

SAFETY

High standard of training, regularly inspected equipment, and reduced personnel make ropes the safest method of access

CLIENT NEED

Vendor scaffolding collapsed

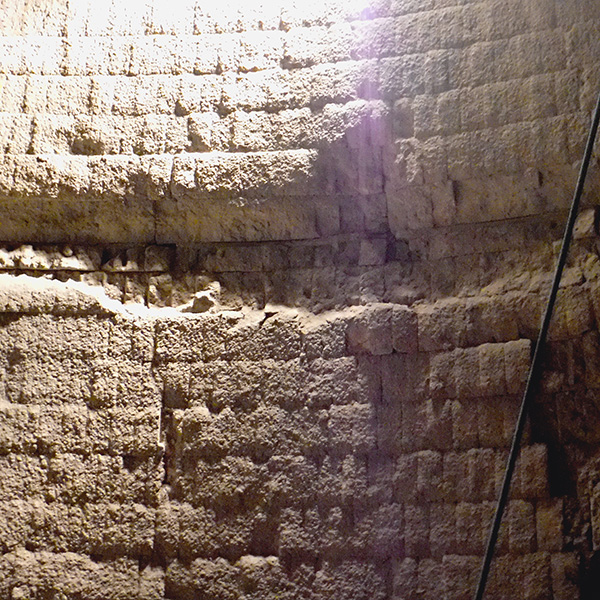

Damage in brickwork from the collapse

Debris of damaged liner and scaffolding pieces

SOLUTION

Using rope access to take scaffold apart

Work in progress

Cutting the scaffolding apart

Cleanup of debris

Applying gunite - no scaffold needed

RESULTS

For additional information about our company and services we provide, please give us a call anytime

770-255-1313