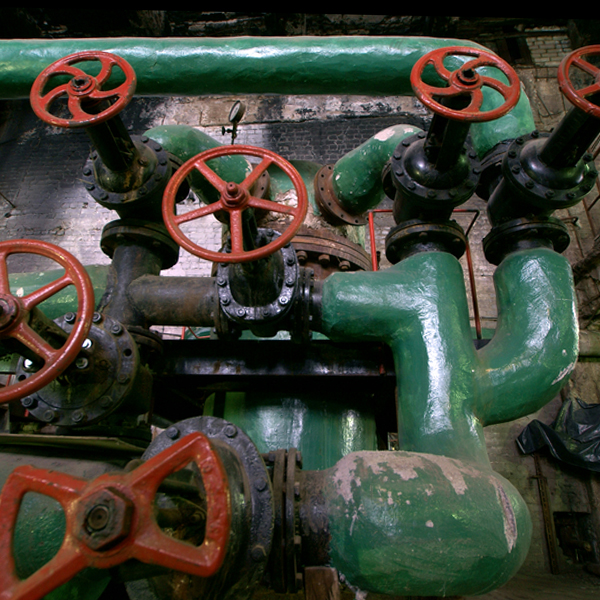

Valve Repair & Maintenance

The Flue Gas Desulfurization (FGD) process requires many different components to run efficiently. At IA Mechanical, we work to repair all aspects of these FGD systems to ensure maximum efficiency. With recent growing federal regulations, FGD systems have become required more often than ever before. Exhaust gases can contain substances that are harmful to the environment, so this system has become essential to meet regulations.

During the FGD process, a corrosive and abrasive limestone slurry is used to complete the desulfurization process. Since this is slurry can break down even the strongest materials, all components must be strong enough to withstand the corrosive capabilities of the limestone slurry. One of these components that must hold up to corrosive materials is the valves used. There are several characteristics of the valves used that contribute to the durability. Between liners, seals, one-piece construction, and injectable packing, valves are designed to withstand corrosive chemicals.

During the FGD process, a corrosive and abrasive limestone slurry is used to complete the desulfurization process. Since this is slurry can break down even the strongest materials, all components must be strong enough to withstand the corrosive capabilities of the limestone slurry. One of these components that must hold up to corrosive materials is the valves used. There are several characteristics of the valves used that contribute to the durability. Between liners, seals, one-piece construction, and injectable packing, valves are designed to withstand corrosive chemicals.

Valve Design Components

Liners

One important piece of all valves is the replaceable urethane liner. As needed, this liner should be replaced to make sure it is performing as well as it can. This protects the valve body from the limestone slurry. This also protects the seal and helps it remain hard to withstand the abrasive material.

Seal

There is also a perimeter seal on the valve that shuts and ensures no limestone slurry drips into the environment. These valves are installed to be routed to the nearest process trench or drain line. Even though materials are generally resistant to corrosion, these seals should be maintained to make sure that they don’t break down.

Valve Design

Regarding valve design, there is a one-piece perimeter and chest design which minimizes opportunities for leaking. This design also completely encloses the injectable packing which prevents contamination of the limestone slurry.

Injectable Packing

Injectable Packing

This allows for easier disassembly or removal of the valve if need be. Depending on the age and quality of products used to determine how often replacements will be needed.

All of the above features provide reduced cost and easy maintenance overall – especially if kept up with relatively regularly.

If any issues arise with valves in your FGD process, it is important to pinpoint the issue and fix it as soon as possible. Since valves are meant to prevent spillage of potentially harmful chemicals into the environment, repair should not be put off. While fixes may be simple, they can lead to larger issues if neglected. To keep up with compliance, it’s important to ensure that valves have not cracked or have no broken seals. Additionally, regular maintenance will ensure that the most up-to-date products are used.

To ensure that all aspects of the FGD process are running smooth and minimize the risk of running into issues, make sure to check that your valves are operating as they should regularly. For any operating or efficiency issues, call IA Mechanical. No job is too big or complex for us. We prioritize fast and quality service because we know that time means money for your business.