Cement & Lime

WORK PERFORMED

- Upper brick liner restoration

- Concrete windscreen reforming & steel cap installation

- Exterior concrete column crack repairs

- Carbon fiber wrap installation

- Tension band repair & installation

- Hydro-blasting stack exterior & interior

- Interior fly ash removal

- Exterior coating services

- Installation of new ladder, appurtenances & LPS

SUMMARY

TIME

Around 1.5 months to complete

COST

Completed during a pre-scheduled outage

SAFETY

Completed without any near misses or safety incidents

CLIENT NEED

ACCESS

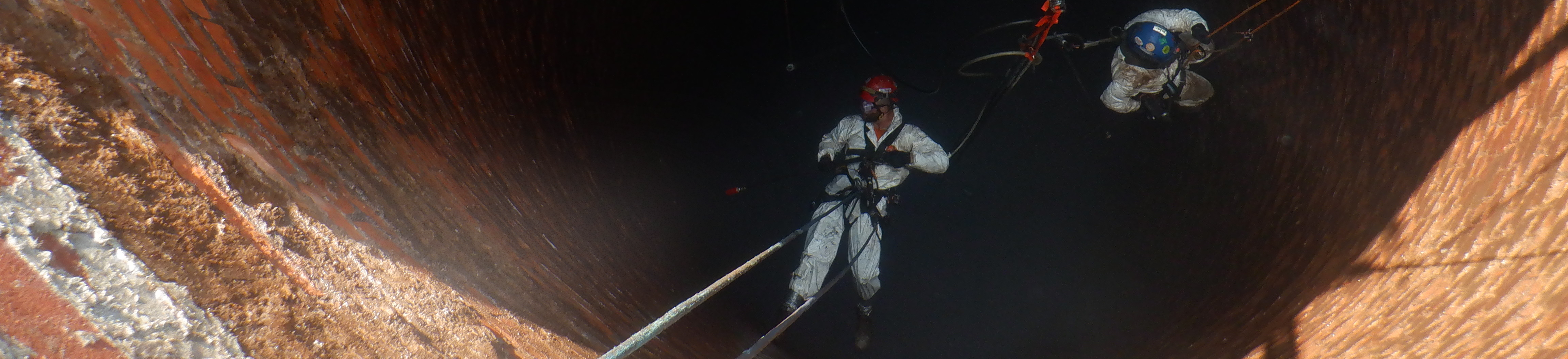

Stack before repairs

Top section of the stack in very poor condition

Rebuilding liner after demolishing top 20' of deteriorated brickwork

New windscreen installed

Patching and prepping areas for carbon fiber reinforcement

Top section of the chimney repaired, steel caps installed

SOLUTION

Installing a carbon fiber wrap to top 25' section

Repairing cracks across stack column

Installing new steel tension bands

Installing a protective coating system

Platform, ladder, cable climb installed

Stack services complete

RESULTS

For additional information about our company and services we provide, please give us a call anytime

770-255-1313