Cement & Lime

WORK PERFORMED

- Installation of scaffolding & access openings

- Removal of interior baffle wall

- Installation of silo cylinder reinforcement system

- Reinforcement of silo support structure

- Installation of new material inlet system

- Coating of silo exterior

SUMMARY

TIME

Project completed over several months with single mobilization

COST

Many items did not require outage

SAFETY

Completed without any near misses or safety incidents

CLIENT NEED

Silo to be reinforced

Silo cylinder reinforcement

Leg reinforcements

ACCESS

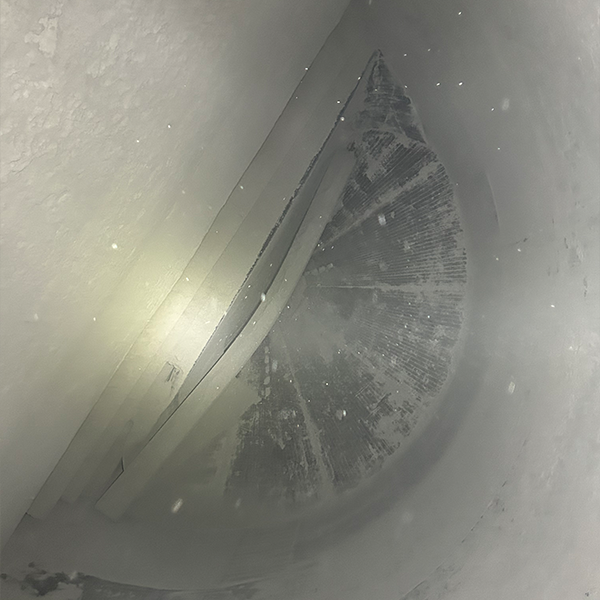

Baffle wall with material buildup

Clogged baffle wall demolition

Baffle wall removed

SOLUTION

Priming and painting the silo

Silo roof reinforced and coated

Silo reinforcement and coating complete

RESULTS

For additional information about our company and services we provide, please give us a call anytime

770-255-1313