Chemicals & Refinery

WORK PERFORMED

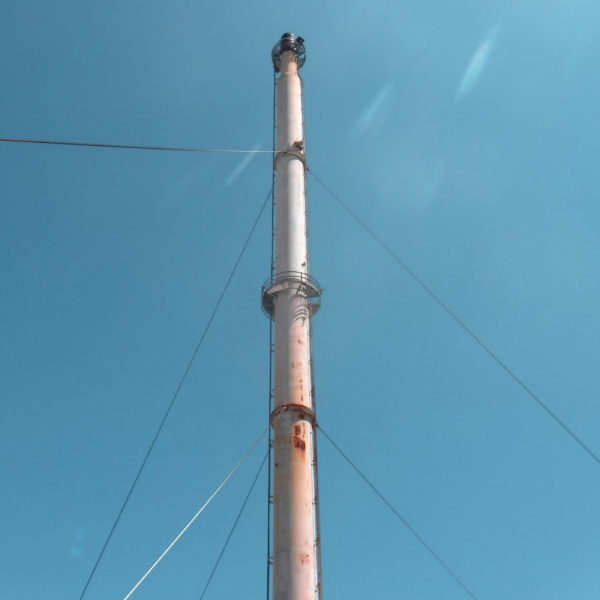

- Washdown of the stack exterior

- Application of a new exterior protective coating system

- Replacement of Aircraft Warning Light system

- Replacement of a portion of the ladder + other minor repairs

- Replacement of the top platform grating

SUMMARY

TIME

1-2 weeks with mobilization

COST

Cost-effective, yet reliable repair solutions

SAFETY

Completed with no safety compromises

CLIENT NEED

Deteriorating flare stack

Platform grating heavily corroded and partially missing

Ladder sections and other stack elements corroded

ACCESS

Stack exterior access

Washing down the stack

Applying new coating

SOLUTION

Installing new safety gates

New AWL system installation

New ladder and cable climb installed

Finishing up the paint job

New safety gates, platform grating and steel paint

Stack repairs and coating complete

RESULTS

For additional information about our company and services we provide, please give us a call anytime

770-255-1313