Power Generation

Work Performed

- Inspection of liners and breeching duct

- Setup of a stack interior access platform

- Removal of hardened flyash buildup on liner wall

- Brick repair

- Disposal of removed buildup

Summary

TIME

5-6 weeks with inspection and repair

COST

Completed during scheduled outage window and within budget

SAFETY

Entry from above allowed technicians to work top-down while staying above falling hazards

Client Need

Cross-beam swing stage assembled on land

Helicopter placing the swing stage

Structure placed on top of the liner

Access Approach

Work platform suspended inside the liner

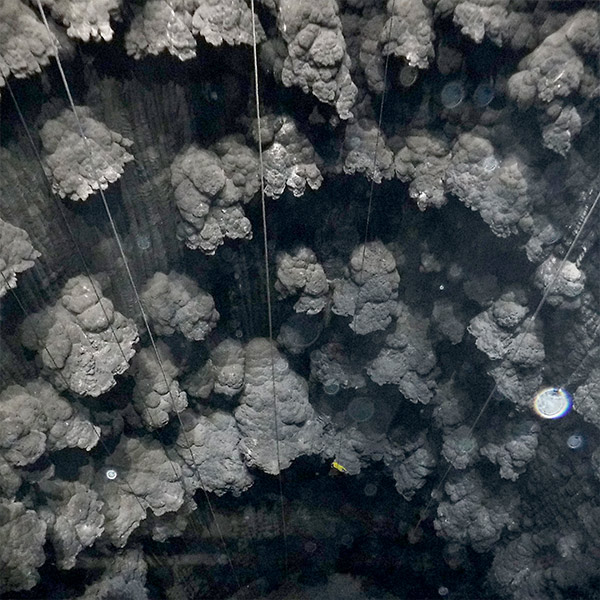

Excessive material buildup at the bottom

Scale of material buildup shown

Solution

Liner wall buildup cleanup

Pieces of buildup dislodged

Cleanup process in the duct

Results

For additional information about our company and services we provide, please give us a call anytime

770-255-1313