Mining & Minerals

WORK PERFORMED

- Installation of access doors and platforms

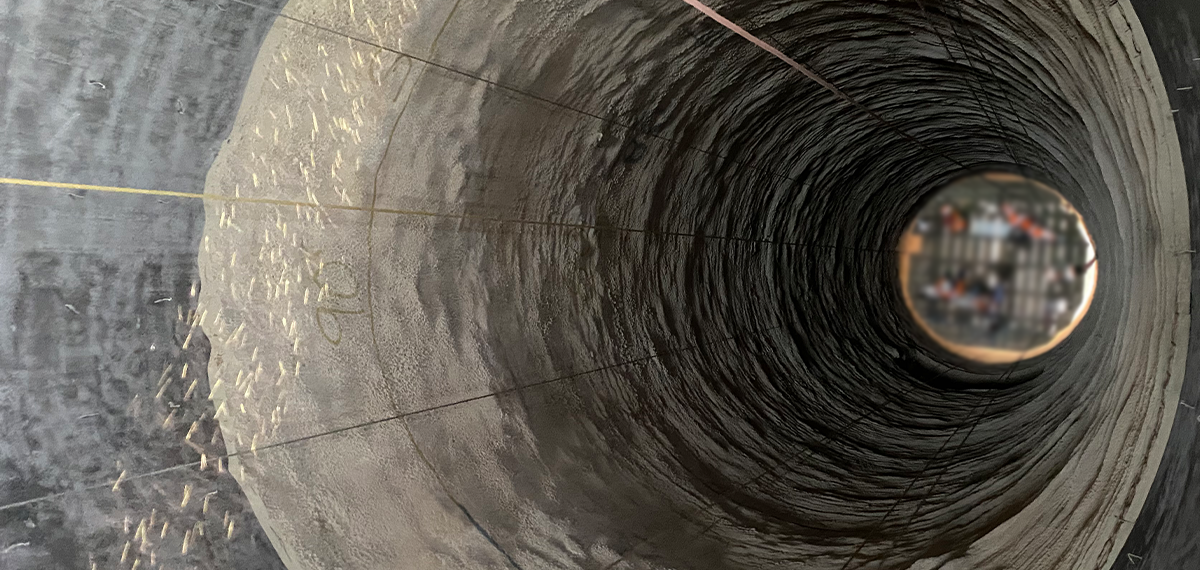

- Demolition of ~150’ spalled refractory

- Application of new gunite liner

- Removal and reinstallation of conical top

SUMMARY

TIME

Around a month to complete

COST

Completed during a pre-scheduled outage

SAFETY

Completed without any near misses or safety incidents

CLIENT NEED

Boiler in need of liner repair

Liner deterioration

Spalling liner at top

ACCESS

New access door installed

Liner demolition in progress

Debris cleanup through temporary access door

SOLUTION

Steel prepped for new gunite application

Gunite application

New gunite refractory

RESULTS

For additional information about our company and services we provide, please give us a call anytime

770-255-1313