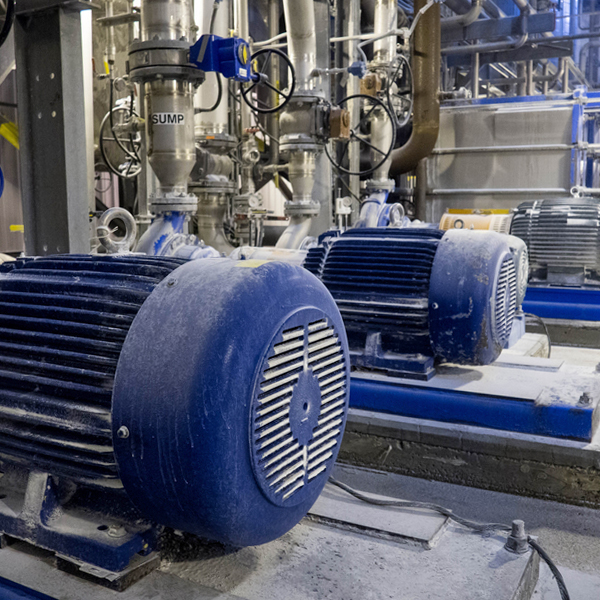

Sump Pump Repair & Maintenance

Flue Gas Desulfurization (FGD) devices require many different components to run efficiently. At IA Mechanical, we work to repair all aspects of these FGD systems to ensure maximum efficiency. With recent growing federal regulations, FGD systems have become required more often than ever before. Exhaust gases can contain substances that are harmful to the environment, so this system has become essential to meet regulations.

Sump Pumps And Their Purpose

Sump Pumps And Their Purpose

Sump pumps are important to the process of flue gas desulfurization. The purpose of sump pumps is to remove accumulations of liquid from a sump pit or any place that water tends to or can accumulate. In the FGD process, there are several areas in which sump pumps can be applied to allow for a smooth process – mainly in the absorber unit. In areas where there is a chance for water to collect at the bottom of the tower or liquid vessel, sump pumps can be installed. Not all systems elect to use sump pumps, but they are a valuable addition.

Sump pumps are found in the absorber unit just above the drain to the reaction tank. Service water enters this unit and goes through the process. At the top of the absorber, is the mist eliminator which leads to the different chimney flues. There is also an exit valve to the primary dewatering from the absorber unit as well. The sump pump takes care of any remaining water at the bottom of the tank to ensure all runs as planned.

As it could be imagined, if a sump pump isn’t working as it should, then issues related to water buildup could arise. If this happens at your plant or facility, it is important to contact IA Mechanical as soon as possible. Not only could this cause damage to equipment and minimize potentially reusable gypsum, but it could also emit toxic chemicals at the facility or nearby environment. This could also cause compliance issues due to federal regulations.

Regular Sump Pump Maintenance

Regular Sump Pump Maintenance

In addition to any unexpected issues with your sump pump, regular maintenance is important to keep the system working as usual and keep within federal regulations. Regular upkeep can prevent or minimize any problems down the road. Making proactive upgrades before they are critically needed could prevent future emergencies that can be costly. This will also ensure that the entire FGD process is running smoothly, and all components used in the process can be checked on as well.

To ensure that all aspects of the FGD process are running smooth and minimize the risk of running into issues, make sure to check that your sump pump is operating as it should regularly. If there is any unusual water buildup present, this could turn into a larger issue if neglected. For any operating or efficiency issues, call IA Mechanical. No job is too big or complex for us. We prioritize fast and quality service because we know that time means money for your business.