Cement & Lime

WORK PERFORMED

- Inspection of stack & duct systems

- Removal of failed TMD & top stiffener ring

- Installation of 4 interior reinforcement rings

- Installation of exterior vertical stiffener system

- Weld repairs & patch plating

SUMMARY

TIME

Project completed in 2-3 weeks

COST

Completed during a pre-scheduled outage

SAFETY

Completed without any near misses or safety incidents

CLIENT NEED

371' Kiln stack

Steel degradation at knee brace

Steel shell in poor condition

ACCESS

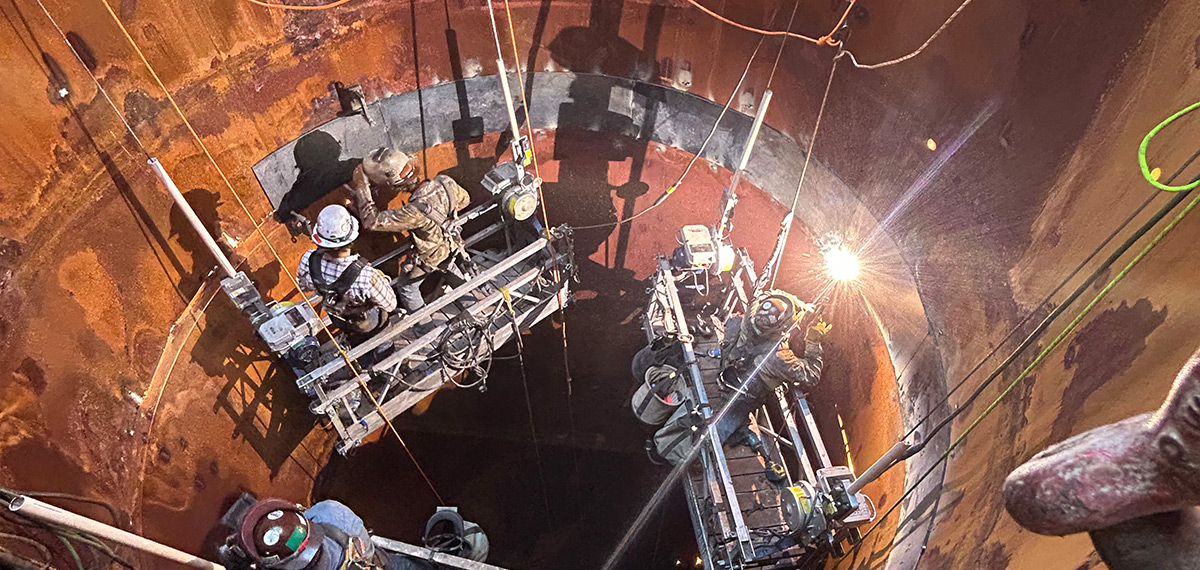

TMD demo in progress

Vertical stiffeners installed

Vertical stiffeners installed

SOLUTION

Interior reinforcement installation in progress

Ring reinforcements at top platform el.

Reinforcement rings at CEMS platform el.

RESULTS

For additional information about our company and services we provide, please give us a call anytime

770-255-1313