We Resolve Storage Structure Flow Issues

Poor flow of assets in storage structures is troublesome for businesses, and there are several causes for it. With regular silo inspection and maintenance, flow issues often don’t have to cause long-term slowdown of assets. Industrial Access Bulk Materials can help with any flow issue you may be encountering with any of our various solutions.

Below are common types of flow issues:

Funneling

Funneling occurs when the product is not not evenly flowing out, causing a blockage and residing in stagnant zones.

Ratholing

The material forms a narrow passageway above the feed auger or outlet. In contrast, the remaining materials on the sides of the passageway are stationary and can begin caking to the walls.

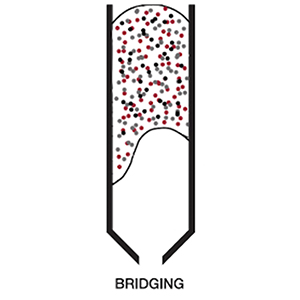

Arching / Bridging

Arching or bridging occurs when material becomes stuck together. Over time, this creates an arch-shaped blockage way up from the discharge.

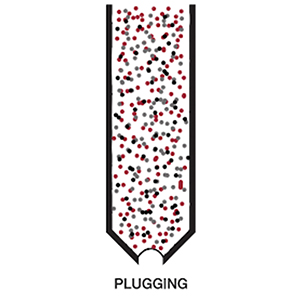

Plugging

Plugging can occur when your unit becomes built up, without allowing flow.

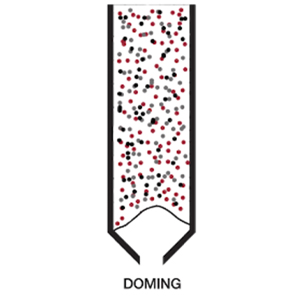

Doming

Doming is another way to describe a bridging issue, they both form arches over the discharge.

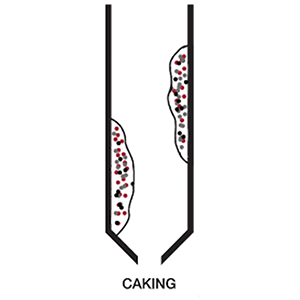

Caking

Caking occurs when the material builds and compacts on the sides. If not solved when it becomes apparent, this buildup can lead to other flow issues, like doming or plugging.

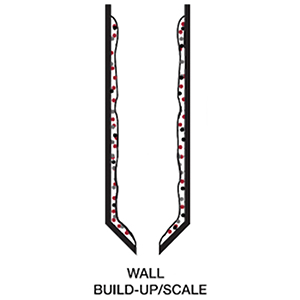

Wall Build-Up / Scale

When build up on the wall occurs, it reduces your storage capacity as well as causes uneven flow patterns.

Arching/Bridging

Arching or bridging occurs when material becomes stuck together. Over time, this creates an arch-shaped blockage way up from the discharge. Any material above the arch cannot flow. This type of flow issue can result in a complete material blockage if attention isn’t given to it. It can also cause long-term damage if neglected due to the extreme pressure it places on the walls.

Ratholing

Ratholing occurs when there is excess buildup on the walls of a storage structure, creating a thin and restricted passageway for materials to flow down. The material forms a narrow passageway above the feed auger or outlet. In contrast, the remaining materials on the sides of the passageway are stationary and can begin caking to the walls. This is important to avoid as many materials get wasted when this blockage occurs.

Funneling

Funneling occurs when the product is not evenly flowing out, causing a blockage and residing in stagnant zones.

Plugging

Plugging can occur when your unit becomes built up, without allowing flow.

Doming

Doming is another way to describe a bridging issue, they both form arches over the discharge.

Caking

Caking occurs when the material builds and compacts on the sides. If not solved when it becomes apparent, this buildup can lead to other flow issues, like doming or plugging.

Wall Build-Up / Scale

When build up on the wall occurs, it reduces your storage capacity as well as causes uneven flow patterns.

Why do these happen?

There can be many reasons why you may be experiencing flow or build up issues. A common cause could be from moisture getting into your commodity. This could happen from a roof leak, errors in the drying process prior to being stored, or cross-contamination. These all go into effect when proper routine maintenance is not performed. By doing so, it allows the facility to catch any issues early on prior to the atmosphere getting into the unit.

Silo Cleanout Services & Solutions

Silo Cleanout Services & Solutions

We have several silo cleanout methods to get you back to regular production. Industrial Access Bulk Materials is trained and equipped to handle any buildup, flow issue, or blockage you may encounter. No issue is too severe for us to handle. We have several different resources and methods to get your silo flowing back to how it should be. Industrial Access Bulk Materials possesses over 14 different tools and methodologies to empty your bulk storage vessel quickly and efficiently. Our team of experts will be able to assess your structure and create a customized solution to get the job done.

Fill out our Silo data form contact sheet to speak with an expert!