Pulp & Paper Storage Inspection & Cleaning

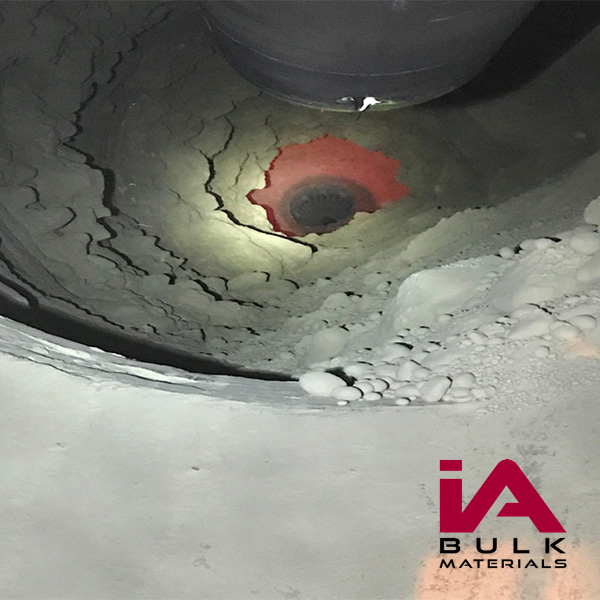

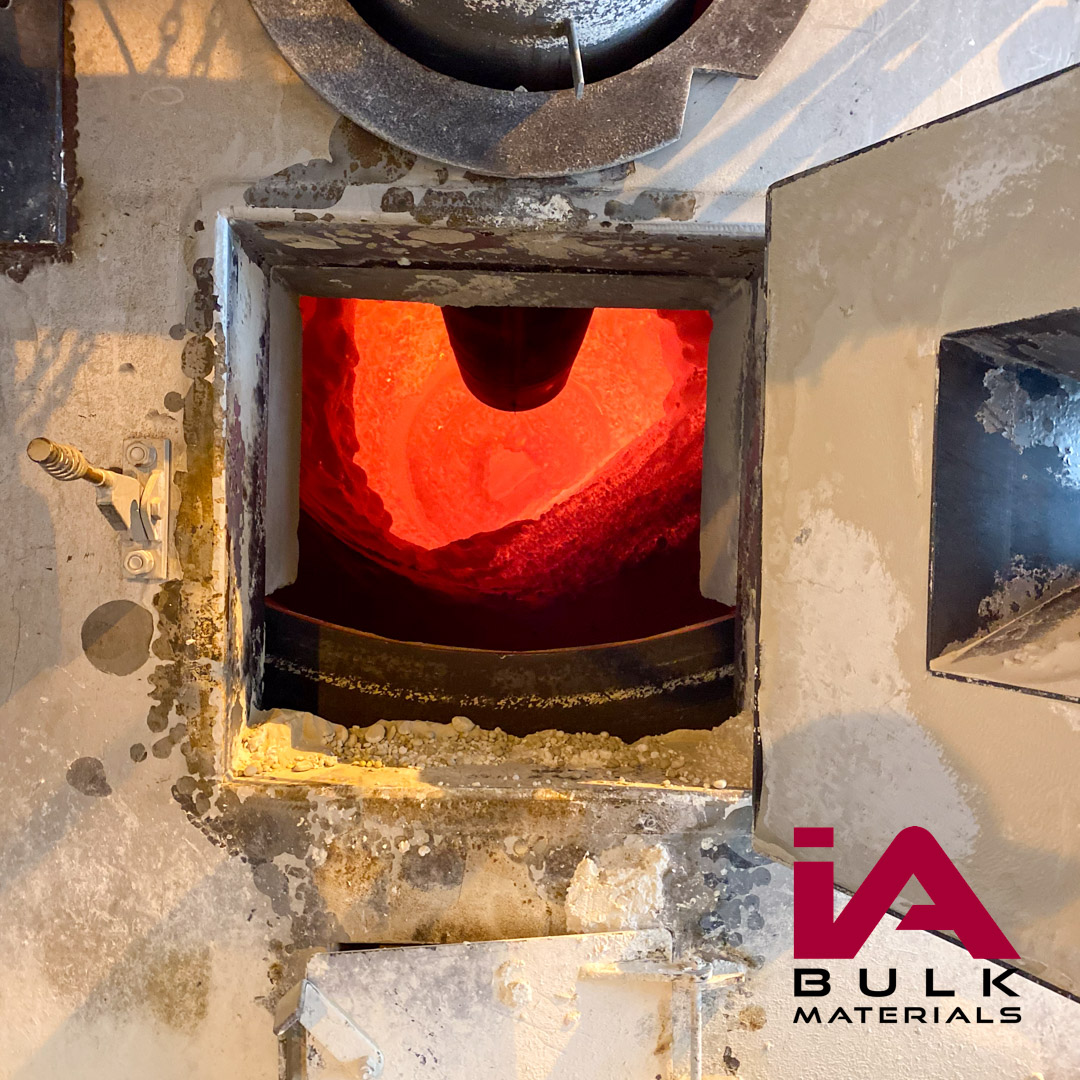

IA Bulk Materials is equipped to address any buildup or flow challenges you may encounter in your Chip Bin, Hot Lime Silo, Boiler, or Rotary Kiln. With our extensive experience in the Pulp & Paper Industry, we understand the critical role maintenance plays in optimizing productivity.

Solutions

With our combined training, experience, and safety precautions, IA Bulk Materials is qualified to handle any issue your bulk storage vessel may face. We understand the importance of keeping your facility running at 100% capacity and unfortunately have seen the risks of going too long without maintenance. With a knowledgeable background in this industry, you can trust IA Bulk to help get your facility back to where it needs to be. Please see our Rotary Kiln Page for more information on our services.

Call Industrial Access Bulk Material

Call Industrial Access Bulk Material

At Industrial Access Bulk Materials, no job is too large or complex for us to complete. Our team is equipped and experienced to fix any minor or major issue. We can also work with you to develop a routine maintenance plan to avoid larger issues down the road. We pride ourselves on providing the highest quality of service in as little time as possible to save you money and downtime. Call us today and we can find what solutions are right for your facility.